Overview

Provides the required confidence that pest prevalence is acceptably low within the registered site, when the commodity is vulnerable to infestation.

- Examples of where an LPPS can be applied include in production or post-production systems where pest prevalence is already expected to be low for environmental reasons or because of existing pest management practices.

- An LPPS is verified through on-site surveillance, and has requirements for corrective action or suspension if agreed thresholds are exceeded. Evaluating the efficacy of LPPS measures requires demonstrating that infestation risk will remain acceptably low provided the threshold for suspension is not exceeded.

- Application of an LPPS measure can range from recognition of existing commercial practices through to strict regulatory oversight. It can be used as a stand-alone phytosanitary measure or combined with other dependent or independent measures.

- Assurance can be achieved through record maintenance and physical audit, or direct oversight, of key components of an LPPS measure by the NPPO or relevant authority of the exporting jurisdiction.

Evidence to support efficacy

Evidence must provide sufficient confidence that maintaining pest prevalence at, or below, the specified maximum acceptable infestation rate will manage risks to the level required by the LPPS measure This includes providing evidence to support the key components of an LPPS measure. Namely, the surveillance design, the maximum acceptable infestation rate, agreed thresholds for corrective action and suspension that ensure that this rate is not exceeded, and the efficacy of corrective actions.

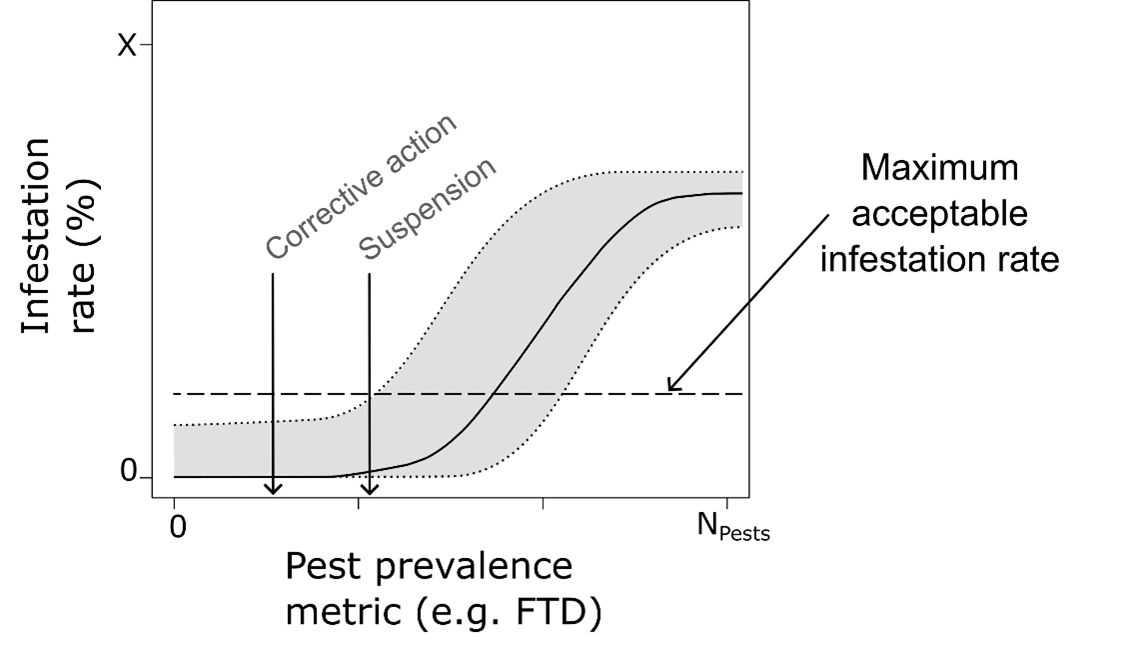

The application of an LPPS measure requires there to be a relationship between pest prevalence, as estimated through surveillance, and infestation risk in the target commodity (Figure 1). This relationship is then used to identify a maximum acceptable infestation rate, and to specify suspension threshold that will ensure that this infestation rate is not exceeded. A corrective action threshold can be specified to initiate management actions aimed at preventing suspension. An LPPS measure may not be appropriate where there is too much uncertainty surrounding the relationship between the estimate of pest prevalence (e.g. trap catch) and infestation risk.

Surveillance conducted on the registered site needs to be sufficiently sensitive to detect the pest at the specified level (i.e. low pest prevalence), with an appropriate level of confidence. Surveillance requirements may be less onerous than for Pest Free Sites because the aim is not to demonstrate pest absence. Considerations for surveillance design include surveillance method (e.g. trapping, visual crop inspections or destructive sampling), surveillance effort (e.g. the duration and frequency of surveillance, trap density or number of plants inspected), how surveillance is distributed across the site (e.g. regular or perimeter-biased trap placement), factors that might interfere with surveillance, and biological characteristics of the pest (e.g. dispersal ability, detectability and trapability).

Quantitative, achievable threshold criteria for the application of corrective actions or suspension need to be based on scientific evidence. This includes selecting a pest prevalence metric (e.g. average pests per trap per week at a specified trap density) that best reflects the relationship between pest prevalence and infestation risk within the registered site, for a given surveillance design (Figure 1). The proposed corrective actions must demonstrably reduce the risk of suspension thresholds being exceeded, without interfering with surveillance sensitivity.

Confidence in the efficacy of an LPPS measure can be gained through trial implementation of an LPPS measure in diverse production sites. Commencing site-based monitoring prior to when the commodity becomes vulnerable to the pest can provide added confidence that pest prevalence is low when infestation can occur. Confidence also increases if there is evidence that pest prevalence in the area is low, if the pest has a limited dispersal ability and is unlikely to enter the sites(s) from non-cultivated hosts, or the site(s) are geographically isolated.

The application of an LPPS requires that there is a measurable relationship between a surveillance metric, used as a proxy for estimating site pest prevalence, and infestation rate. This relationship is used to identify a maximum acceptable infestation rate, at or below which the risk of infestation is acceptably managed, and to specify corrective action and suspension thresholds to ensure that this rate is not exceeded. There may be some uncertainty surrounding this relationship, represented by the grey shaded area.

Applying the measure

How it is used

Pest monitoring and corrective actions are frequently implemented as standard practice during production to limit economic losses. These practices can be recognised during a pest risk assessment, or applied as a phytosanitary measure to manage risks.

LPPS measures are used where pest prevalence can be readily monitored, for example through trapping or visual surveillance, and where there is a strong relationship between monitored pest prevalence and infestation risk. It is often applied in systems where pest prevalence is already expected to be below the suspension threshold.

LPPS measures can be applied both during production and, less often, during post-production. For example, in fruit production, trapping or regular crop inspections are often required through the season for multiple quarantine pests such as pathogens, mealybugs and fruit flies. Here, the goal is to provide confidence that the pest is, at most, rare within the registered site. Similarly, it could, for example, be applied to potential hitchhiker pests in shipping container holding yards.

Use with other measures

LPPS measures can be combined with other dependent measures that are also acting to limit pest exposure risks such as pest management (e.g. removal of alternative hosts), pest avoidance (e.g. limiting production to poor pest habitats) and pest exclusion measures (e.g. protected facilities).

For higher-risk pests, an LPPS measure is regularly combined with independent measures into a phytosanitary systems approach. For example, it can provide assurance that infestation rates are low prior to application of a treatment such as irradiation. It can also be combined with treatments that do not achieve high efficacy (e.g. the probit 8.7 benchmark which corresponds to a mortality rate of 99.9968 %), with minimise host vulnerability measures (e.g. developmental stage specifications for fruit maturity standards), and with measures that reduce establishment risk (e.g. restricted end-use and seasonality of imports).

Similar measures

LPPS and Pest Free Site measures can both have a zero-tolerance for pest detections. However, a site with an LPPS measure is not assumed to be pest-free, even if no pests are detected.

An LPPS measure differs from Area of Low Pest Prevalence (ALPP) in terms of geographic scale, the required duration of low pest prevalence status, and consequences for exceeding the agreed thresholds. Under an LPPS measure the consequence of exceeding the LPPS thresholds is only applied to those registered site(s) that exceed them. In some cases, LPPS and ALPP measures could be combined.

Both LPPS measures and Integrated Pest and Disease Management (IPDM) use surveillance with a pest action threshold to guide management activities (or corrective actions for LPPS). However, they differ in focus. The LPPS measure has a greater emphasis on surveillance design and low pest prevalence levels, whereas IPDM uses surveillance and action thresholds to guide the timing and application of pest management practices.

Assurance of correct implementation

Registration of each site and records of the application of key components of the LPPS measure may be required. Depending on the method and the level of assurance required, this could include:

- records of the surveillance program (for example, trap placement, how frequently the traps were checked, any pest detections and diagnostic tests used), records of the triggering of any corrective actions that are applied (e.g. dates of pesticide spraying), as well as suspensions and reinstatements

- records of the application and effectiveness of any additional supporting or dependent measures like buffer zones, or post-harvest treatments

- requirements for consignment labelling to allow trace back to specific LPPS’s.

The required assurance will also influence who is directly responsible for each component of an LPPS, and the level of training and oversight that is required for each. In some cases, physical inspection of the registered site and audit of the records can be conducted by authorised personnel at an appropriate interval, with oversight by the NPPO or relevant authority of the exporting jurisdiction.